The Best Wooden Paddleboards That Aren't Too Heavy to Lift

31st Oct 2019

Why is it so hard to find wooden stand-up paddleboards? Builders in California and around the world have been making stunning surfboards out of wood for years.

The main reason is weight: Surfboards harness the energy of a wave to keep the board and surfer above the water. Surfers can show off by riding smallish wooden boards and then throwing it over their shoulders for a walk down the beach. But paddleboards have to be much bigger because they rely on plain old buoyancy.

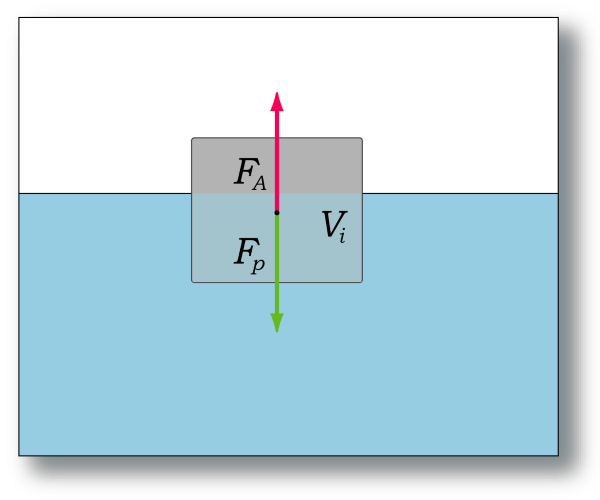

First, a little physics: the buoyant force of a paddleboard—pushing up—must be equal to the weight of the board and its rider pushing down. If the board and rider weigh 240 pounds, then you need a board that, when placed in the water, packs an upward buoyant force of at least 240 pounds.

This is nothing new. The Greek mathematician Archimedes discovered more than two thousand years ago that buoyancy is equal to the weight of the volume of displaced water.

Now let's go back to the man-and-board combination that weights 240 pounds. We know that seawater weighs about 60 pounds per cubic foot, so the man in our example would need a board whose underwater portion has a volume of 4 cubic feet (240 pounds ÷60 pounds per cubic foot), or 113 liters. In reality he'd want a board with a much greater displacement so that a significant portion of the board remains above the water to help with stability and waves.

All this extra displacement means a bigger board (think of a raft). But unlike an old-school castaway's raft, a paddleboard is something you need to lug back and forth to the car or beach house. So the end result is you need something that's both large (large displacement volume) and light. Unfortunately for tree-hugging mariners, a big hunk of wood is heavy.

So here's the problem: How do you produce a large, light board for paddling? Different builders have solved the problem in different ways, and here are some of the most successful tips.

Wood Doesn't Have to Be Heavy

Balsa wood is about one-fifth the density of freshwater or less, so it's a natural choice for things that float. In fact, the word balsa means "raft" in Spanish. In Ecuador, adventurists have used rafts made of balsa logs to cross the Pacific, and surfers have used balsa wood for years. Decades ago, solid balsa boards replaced the super-heavy surfboards that Hawaiians traditionally used to catch waves (lugging 150 pounds up the beach wasn't much fun).

In Australia, Riley Balsawood Surfboards brings in wood from Ecuador to make beautiful, lightweight surfboards made of solid balsa. Unlike the surfer models, his paddleboards use a hybrid construction rather than solid balsa.

Another wood that's drawn interest is paulownia, which is popular in Japan, where it's known as "kiri." Oregon-based Clearwood Paddleboards sells kits made of paulownia.

Think Swiss Cheese

Balsa and other less-dense woods can help, but boards still start to get heavy when built using solid construction. For example, a large balsa paddleboard with a volume of 180 liters could weigh 80 pounds or so—too large for many paddlers to lift onto a car's roof rack.

One solution is to hollow out "chambers" within each board. Designer Ian Balding of Ian Balding Paddle & Surf Co. has used this method for chambered balsa paddleboards.

The chambers sort of resemble the holes in Swiss cheese, and so one firm has what you might call a Swiss-cheese sandwich. Kun_tiqi, which is named for the famous balsa-wood raft voyage out of Ecuador, builds boards using a set of hollow planks. Kun_tiqi's boards are produced in Spain from Ecuadoran balsa and other sustainable, natural products. The paddleboards sell for 1900 euros.

Build It Like a Boat

Air weights almost nothing, so some paddleboard builders are turning out elaborate hollow designs that use wooden strips, ribs and bits of thin decking. It's a lot like a sealed-off boat—the kind with a closed deck rather than open to the sky. Some say the process, often called semi-monocoque or strip planking, is like making an airplane wing—another object that has to be light. A hard shell that supplies much of the strength augmented by an internal frame of ribs and other pieces. The technique produces strong, seaworthy vessels when carefully assembled and glued properly.

In Maryland, Chesapeake Light Craft (CLC) designs and sells kits for amateur builders to make all types of boats, including stand-up paddleboards. Clearwood, the paulownia specialist in Oregon, uses the same basic method. "You can accomplish almost anything in life, including building a strip planked paddleboard," Clearwood says.

A Veneer of Respectability

Some of the best plastic paddleboards have a core of Styrofoam or similar dry foam that is covered with epoxy or another synthetic material to form a rigid shell. Over time, savvy woodworkers have realized they can use thin boards over foam. At Jarvis Boards in Austin, Texas, the workshop's three craftsmen attache eye-catching patterns of light and dark lumber. "Each wood paddle board is made using recycled foam cores and eco-friendly woods," founder Tony Smith says on his website. Typical boards are just 23 to 28 pounds, according to Jarvis Boards.

Another firm, Three Brothers Boards of Daytona Beach, Fla., uses a similar hybrid of wood and other components to produce featherweight boards. The brothers say their 12½ foot "one wood" board has a volume of 210 liters and can support 400 pounds. It weighs only 38 pounds.